| Product code | GME-1083 |

| Product | Concrete reinforcement wire (Steel fiber wire) |

| Steel wires with hooks at both ends, produced in accordance with the TS 10513 standard, are used in concrete reinforcements. | |

| Steel fiber wire is thin and short steel wires placed in ready-mixed concrete and has different diameters and lengths. | |

| A homogeneous distribution is obtained by joining the steel wires with hooks into the concrete. | |

| It can be easily used as concrete reinforcement reinforcement instead of steel mesh. | |

| It saves time and provides ease of application. | |

| Technical specifications: | |

| Tensile strength | Location. 1100MPa |

| It is produced from cold drawn SAE 1006 or SAE 1008 quality wire rod with hooks on both ends, conforming to Class C ASTM A820. | |

| Types: | |

| Print (d) | Length (In) |

| 1.00 mm | 50 mm |

| 0.90 mm | 60 mm |

| 0.75 mm | 60 mm |

| 0.53 mm | 35 mm |

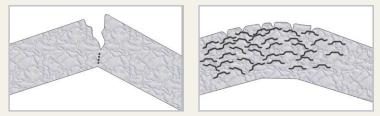

If the steel fiber wires have sufficient strength and the steel wire-matrix bond is used in sufficient and appropriate amounts, it keeps the crack width at a minimum level and enables the concrete to carry loads by making large deformations after the peak load.

Thus, it is possible to obtain concretes with high ductility.

It is used in the following concrete reinforcement applications:

- In field concrete, screed concrete, floor, screed and foundation concretes

- Shotcrete applications (tunnels, slope stabilization, dams)

- In precast concrete castings (panels, concrete pipes)

How to use steel fiber reinforcement wire?

Steel wires sold in packages of 20 or 25 kg are poured into the mixer and added directly into the concrete mortar.

Steel wires are dispersed homogeneously into the mortar and a concrete that can be used without the need for any other load-bearing reinforcement is obtained.

It does not require any additional processing during the pouring and application of the concrete.

Concrete Steel Wire Dosage

The amount of steel fiber fibers (kg/m3) to be added to the prepared concrete primarily depends on the type of steel fiber fiber (diameter and length), maximum aggregate diameter, and whether it is normal or pump concrete.

Determining the most suitable amount of steel fiber wire is only possible after determining the best mix.

In order to achieve much better performance than double-row wire mesh, an average of 20 kg of steel fiber wire can be used in 1 m3 of concrete.

Advantages of Concrete Reinforcement Wires:

- Its tensile strength is 1100MPa, which is twice that of the wires used in steel mesh.

- Its ends are in the form of hooks and provide good anchorage in concrete.

- It increases the energy absorption capacity of concrete.

- The life of concrete is extended.

- Cracks due to temperature change and different hardening process disappear.

- Steel fiber wires act as a bridge over the crack and prevent the crack from propagating.

- Wire mesh transportation and application time are saved.

- For example, a typical floor concrete job that can be done in 10 days will be finished faster.

- This period is much shorter in tunnel or concrete panel and pipe production.

- There is no transportation, laying and transportation of the steel mesh.

- It is laid directly in the concrete mixers.

Steel Wires provide a homogeneous reinforcement distribution in the concrete.

Elasticity of steel fiber concrete increases.

Elasticity of steel fiber concrete increases.

The energy holding capacity of concrete increases.

Crack control is better as the reinforcement is distributed over the whole concrete.

Steel fiber concrete shows higher resistance to dynamic and sudden loads.

In particular, its resistance to the stapling effect has been proven.

More joint opening is provided than the joint opening in classical applications.

Economically with steel fiber concrete;

- The durability of concrete increases.

- The slab thickness is reduced.

- Construction time is shortened.

A 10% – 15% reduction in total cost is achieved.

- For shotcrete

Usage areas of steel wires in shotcrete: Tunnels, mine sites, Embankment, dam stabilization, Dams & waterways, Erosion control, It can be used very easily in buildings and constructions.

- for floor plates

Usage areas of steel wires in floor plates: Factory and workshop floors, floors of heavy-duty industries, aircraft hangars, airports, highways, etc. It is used in places such as ready mixed concrete.

- For prefabricated products

Usage areas of steel wires in prefabricated products: Tunnel section linings, Mine site support blocks, Water tanks and tank partitions, Tilt panels, Sound barriers, etc. It is used by adding it into ready-mixed concrete in products such as